Bio-Based Polymer (IAE)

Bio-Based Polymer(IAE)

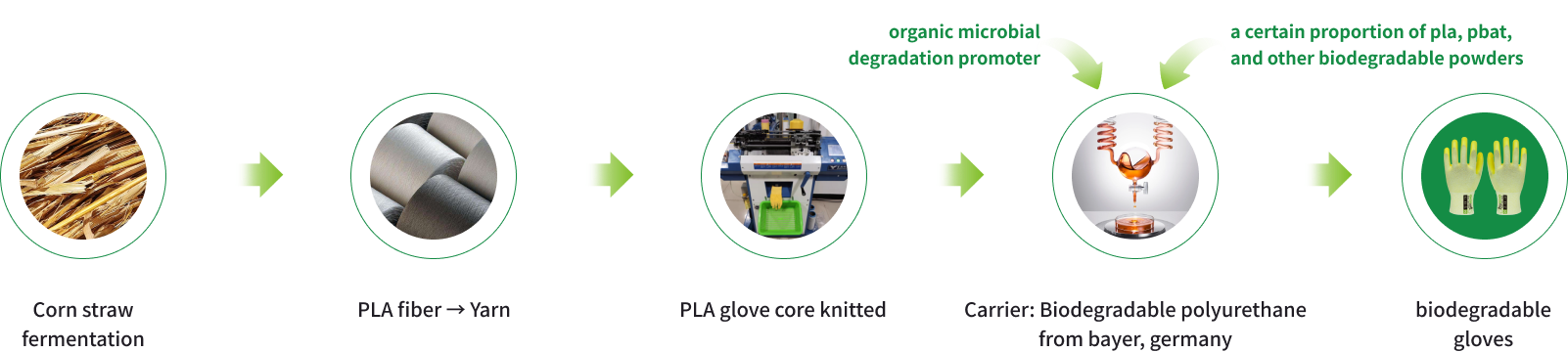

Bio-Based Fiber(PA56)

Recycled Polyester Fiber(R-PET)

Bio-Based Fiber(PA56) Recycled Polyester Fiber(R-PET)

BiConal Production Process

GrenAmr

BiConal Production Process GrenAmr

Dimethyl Formamide

PU Production of plastic AIDS

Dimethyl Formamide PU Production of plastic AIDS

Bio-based polymers are derived from natural (non-food biomass) materials, and the bio-based content is 20% to 80%.

Compared with traditional petroleum-based materials, the production of bio-based polymers per ton can reduce carbon dioxide emissions by about 1.4 tons.

Polyamide, commonly known as nylon (PA), is traditionally derived from non-renewable petroleum resources. The high-temperature and high-pressure production process results in high emissions of wastewater and carbon dioxide, negatively impacting the environment.

To reduce environmental burdens and pollution, PA56 (bio-based nylon), which is renewable and biodegradable, has emerged as a sustainable alternative.

R-PET (Recycled Polyester Fiber) Yarn refers to eco-friendly yarn made from recycled PET products such as discarded plastic bottles. This significantly reduces plastic waste pollution and promotes resource recycling. Unlike virgin PET yarn, it does not require raw petrochemical materials, saving the substantial energy and water consumption needed for producing virgin PET from raw petrochemicals. It notably reduces the consumption of non-renewable petrochemical resources and water, lowering carbon emissions.In terms of quality, R-PET yarn is not inferior to traditional PET yarn in mechanical performance, making it an excellent eco-friendly alternative. Additionally, since its raw materials are recycled, the procurement costs are lower compared to some traditional yarns.

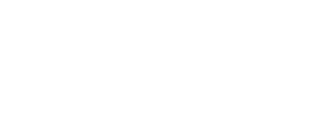

Production Technology: PLA fiber is used as the lining material, while biodegradable polyurethane from Bayer AG, Germany, serves as the carrier.

A certain proportion of PLA, PBAT, and other biodegradable powders, along with organic microbial degradation accelerators, are added to enhance the product's degradation rate under specific industrial composting conditions.

Researchers accidentally discovered that breadworms can eat plastic, so they invented HHMD anaerobic degradation masterbatch.

The factory employs special processes to strictly control the DMFa content in PU gloves, ensuring the health and safety of wearers. During production, advanced distillation and recycling equipment is used to treat and reuse DMFa wastewater. This effectively reduces wastewater and exhaust pollution, lowers energy consumption, and is more environmentally friendly. It also saves costs, providing significant economic benefits.

DMFa is the abbreviation for dimethylformamide. Previously known as "DMF" in the industry, the name was changed to "DMFa" by BVH (Federal Association for Hand Protection) to avoid confusion with dimethyl fumarate (a legally restricted substance used in silicone gel packets and glove packaging to prevent mold). The EN ISO 21420:2020 "Glove Safety" standard stipulates: "The measured fraction of dimethylformamide (DMFa) in PU gloves must not exceed 1000 mg/kg (0.1% by weight). The testing procedure must comply with EN 16778." 0.1% of 1 kilogram: 1,000 grams/kg, where 0.1% by weight is equivalent to 1 gram/kg.

DMF exhibits certain toxicity and can enter the human body through the respiratory tract, skin, and digestive system. It has irritant effects on the eyes, skin, and respiratory tract. Prolonged exposure may cause damage to organs such as the liver. For example, in industrial production environments, workers prolonged exposure to air containing DMF may experience symptoms such as dizziness, nausea, and skin allergies.

After PU dipping, the gloves undergo a water-soaking process to remove DMFa and other substances, significantly reducing the DMFa content in the t the health impacts of product use for wearers.gloves. This eliminates concerns abou

By utilizing advanced distillation and recycling equipment, thermal energy consumption has been reduced by over 35%.

Through energy-saving measures and wastewater recycling, production costs are effectively reduced, enhancing the product's cost-effectiveness.

Unlike traditional PU production processes, the factory recycles and reuses DMFa wastewater, effectively reducing wastewater and exhaust pollution.

Scan the

QR code to view

©2025 Company Name. All rights reserved Copyright: Dumit (Shanghai) Protection Technology Co., Ltd