The 2RABOND Heat-Sealing Technology is our exclusive international patented technology. The basic principle involves using a heat source to heat the glove core and coating until they reach a certain molten state. Under pressure, the materials interpenetrate, forming a strong bond between the Double-Layer Structure materials.

Gloves bonded using 2RABOND Heat-Sealing Technology differ from traditional dipped gloves in the following ways:

Applicable Gloves:

Gloves with a structure consisting of a yarn core + coating.

Applicable Coating Types:

Butyl, chloroprene rubber, etc.

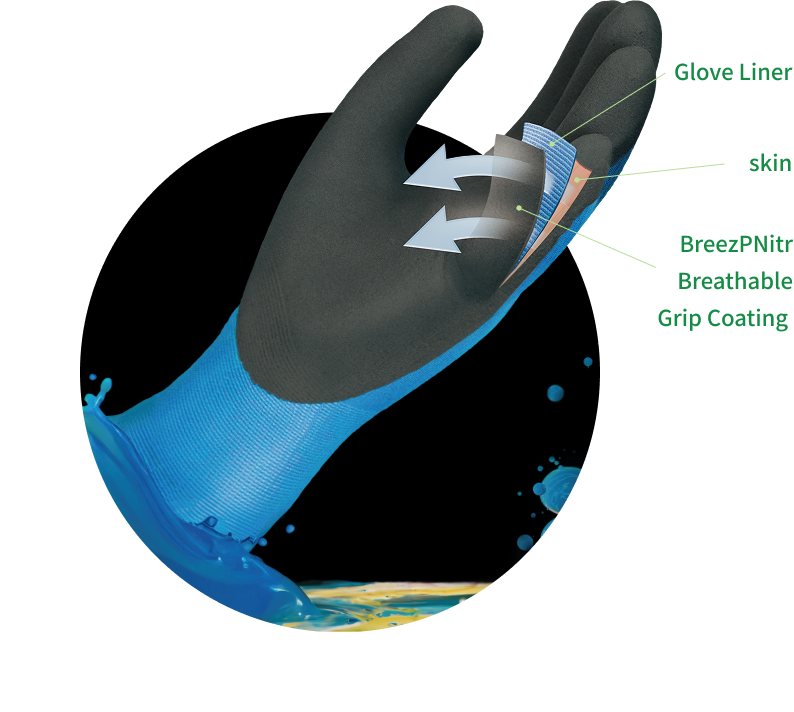

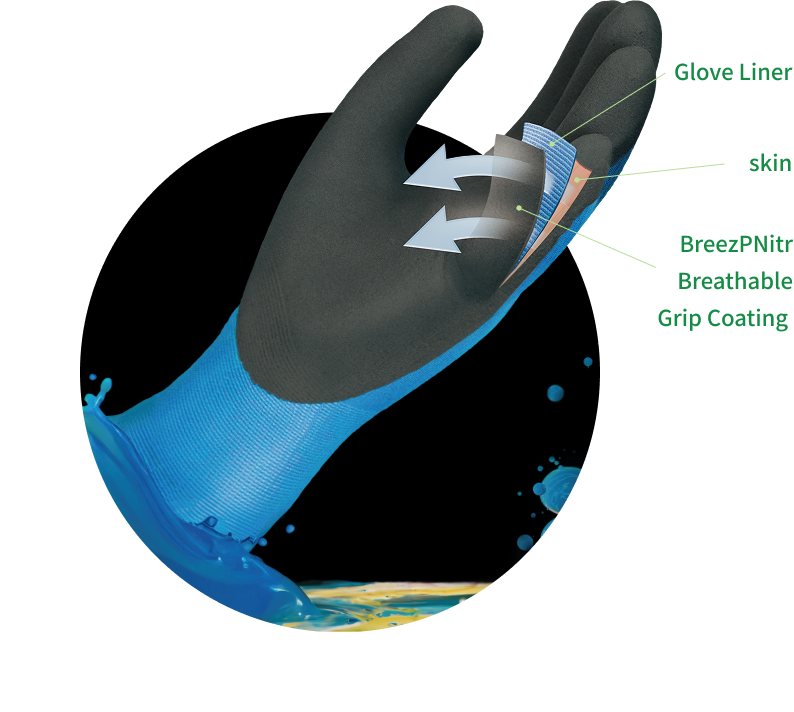

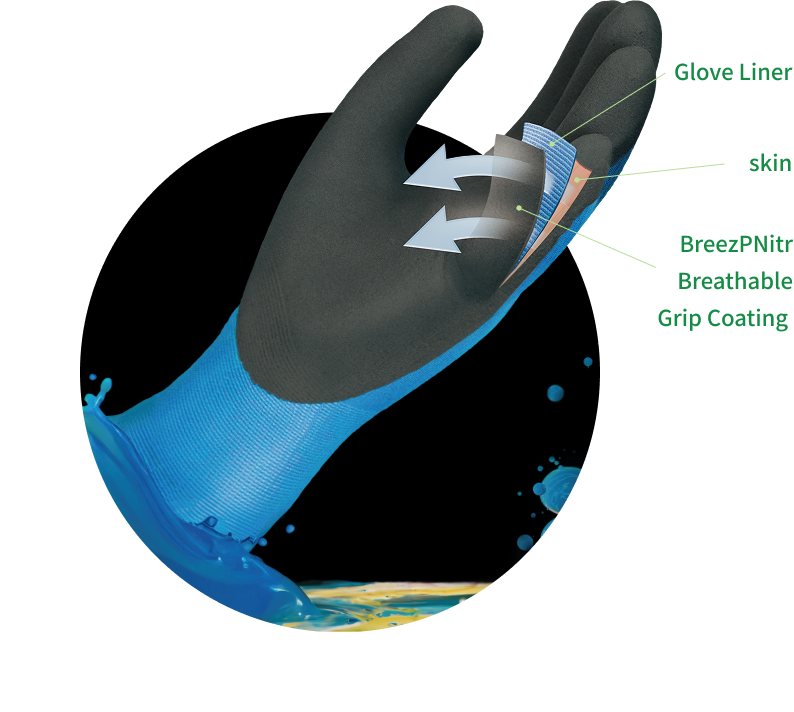

BreezPNitr is a revolutionary coating technology that creates protective gloves with exceptional durability, strong grip, high breathability, flexibility, and oil resistance. These gloves offer safety and softness akin to a mother's embrace. Utilizing more advanced technology, it reduces water usage by 30%, conserving water and minimizing water pollution.

The BreezPNitr coating breathes like skin. With its millions of nano-bubbles, it provides 360° breathability, effectively dissipating sweat and heat from the skin to maintain optimal hand temperature and dryness. This allows you to work more efficiently with peace of mind.

The BreezPNitr coating has undergone European standard abrasion resistance testing, enduring 8,000 cycles (meeting Grade 4 standards). Compared to conventional nitrile sanding and nitrile foam coatings, it shows significantly less wear,minimal shedding, and no visible damage even after 15,000 cycles, demonstrating exceptional abrasion resistance.

Thanks to its unique material and manufacturing process, the BreezPNitr coating offers superior abrasion resistance compared to standard nitrile coatings and other synthetic rubber coatings. This provides more reliable protection for the hands and effectively extends the glove's service life.

The property of minimal shedding makes it suitable for various work environments that require high cleanliness standards (e.g., electronics manufacturing, precision instrument manufacturing, etc.), reducing the impact of glove wear on product quality.

The BreezPNitr coating offers superior tensile performance compared to conventional nitrile foam and other material coatings. It is a highly elastic and high quality coating, known for its relatively softer feel among rubber coating materials. Prolonged wear reduces hand fatigue and enhances work efficiency.

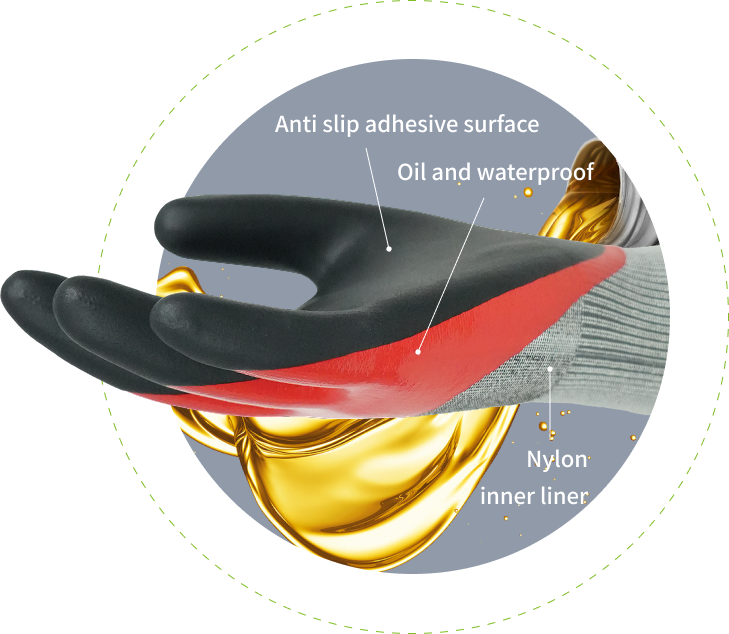

In work environments where gloves need to come into contact with oily surfaces, such as placing palms on oily workbenches or pushing oily equipment, these gloves provide exceptional anti-slip performance. They tightly grip the object, minimizing accidental slips, saving time and effort, and effectively reducing safety accidents and injuries.

In oily environments, these gloves enable wearers to efficiently handle large, medium, and small components with a secure grip, reducing the risk of items slipping. This enhances work precision and efficiency while minimizing safety hazards caused by dropped items.Note: Typically, there are 1–2 layers of nitrile smooth coating between the grip layer and the glove core to ensure better oil resistance and durability.

Scan the

QR code to view

©2025 Company Name. All rights reserved Copyright: Dumit (Shanghai) Protection Technology Co., Ltd